Surface treatment after cross section repair

↑ Finishing Techniques for Concrete Repairs using Shrinkage-free Mortar

-Processed video after placing shrinkage-free mortar. After placing non‐shrinkage mortar in the voids, repair difference in level and different colors to make it beautiful.

Things to prepare yourself

State before finishing

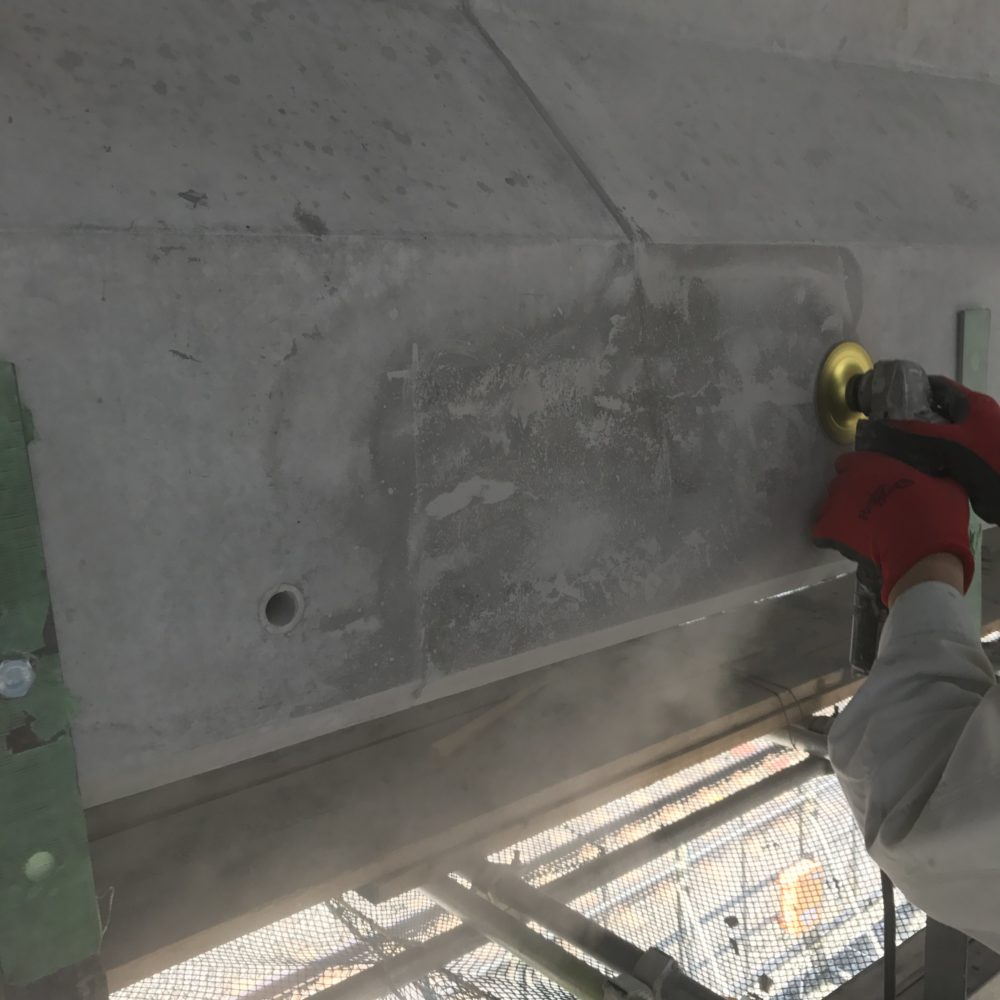

STEP1

Polishing flat to the finished surface level with a diamond cup or a Level Grinding Wheel .

Make sure that there are no more protrusions on the finished surface.

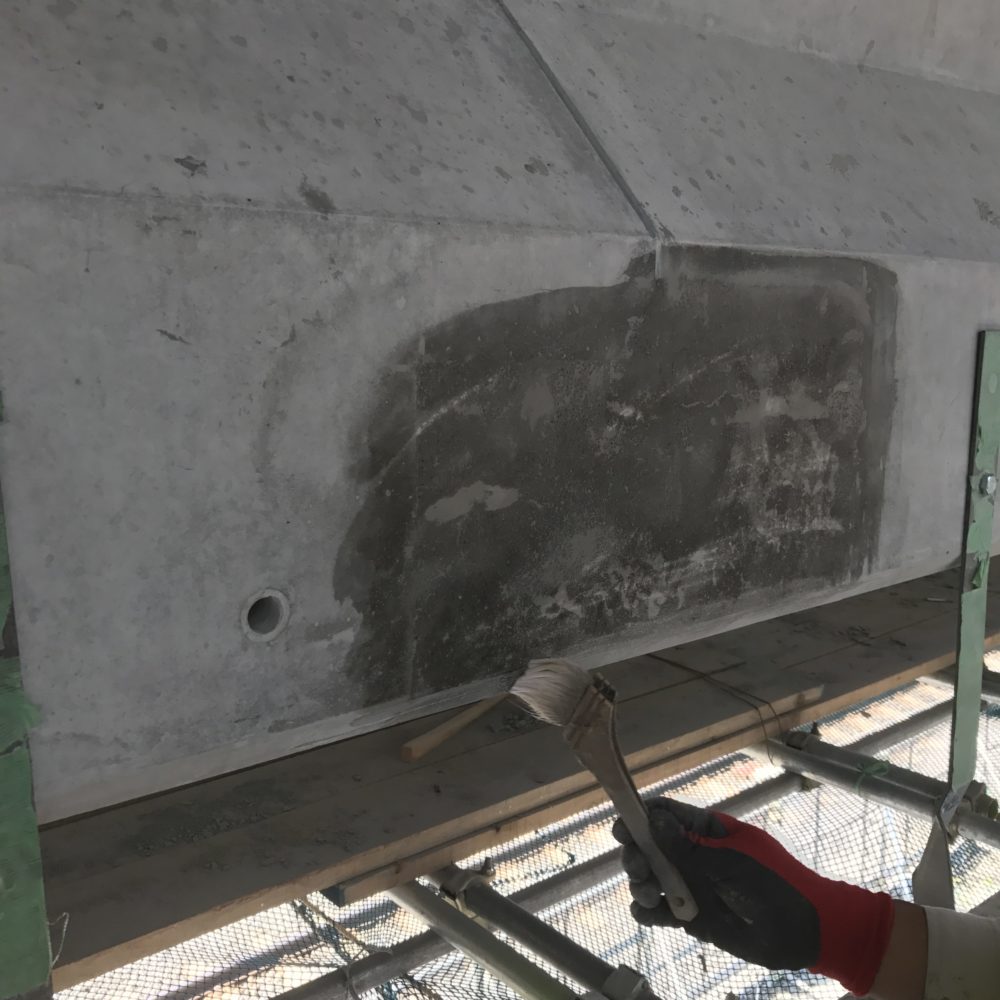

STEP2

Remove dust and dirt and trowel-coating a primer.

Trowel-coating the repair material so that it covers the entire area.

It is an image that fills the finely dented parts and gaps.

It will be flattened in the subsequent shaving process, so let's dare to serve it a little.

STEP3

When the material is half-dried, scrape it off with a trowel or scraper .

If the area is large, it is easy to get a flat surface by polishing with a grinder machine equipped with a grindstone # 80.

* The photo uses a grinder. * When using a grinder , the material should be completely dried.

STEP4

After making sure it is completely dry, trowel-coating the primer again.

* trowel-coating thinly so that it does not drip. Please note that if you apply it thickly, the lining material will not be applied well after this.

* Reference video

・ How to use C Repair Lining

STEP5

Apply the lining material thinly with a trowel for the lining material so that the base can be seen through.

* If the base is dry and difficult to trowel-coating, trowel-coating the primer again.

STEP6

After it has completely dried, remove the borders with the surroundings, trowel marks, and burrs with a scraper or paper to eliminate small difference in level.

The groundwork is complete when the whole is gloss.

STEP7

Seen from a position slightly away from the repaired part, determine the overall finished color.

At first, spray a little and check the color.

Let's add it little by little while drying.

It is OK when the feeling of discomfort with the surroundings disappears and the groundwork disappears.

completion

Use the Tone Color and Pattern pat to add a pattern.

Apply # 600 paper to the surface.

Add joint pattern, stain, and unevenness to eliminate discomfort with the surroundings.

If there is no discomfort, it is complete.

State before construction

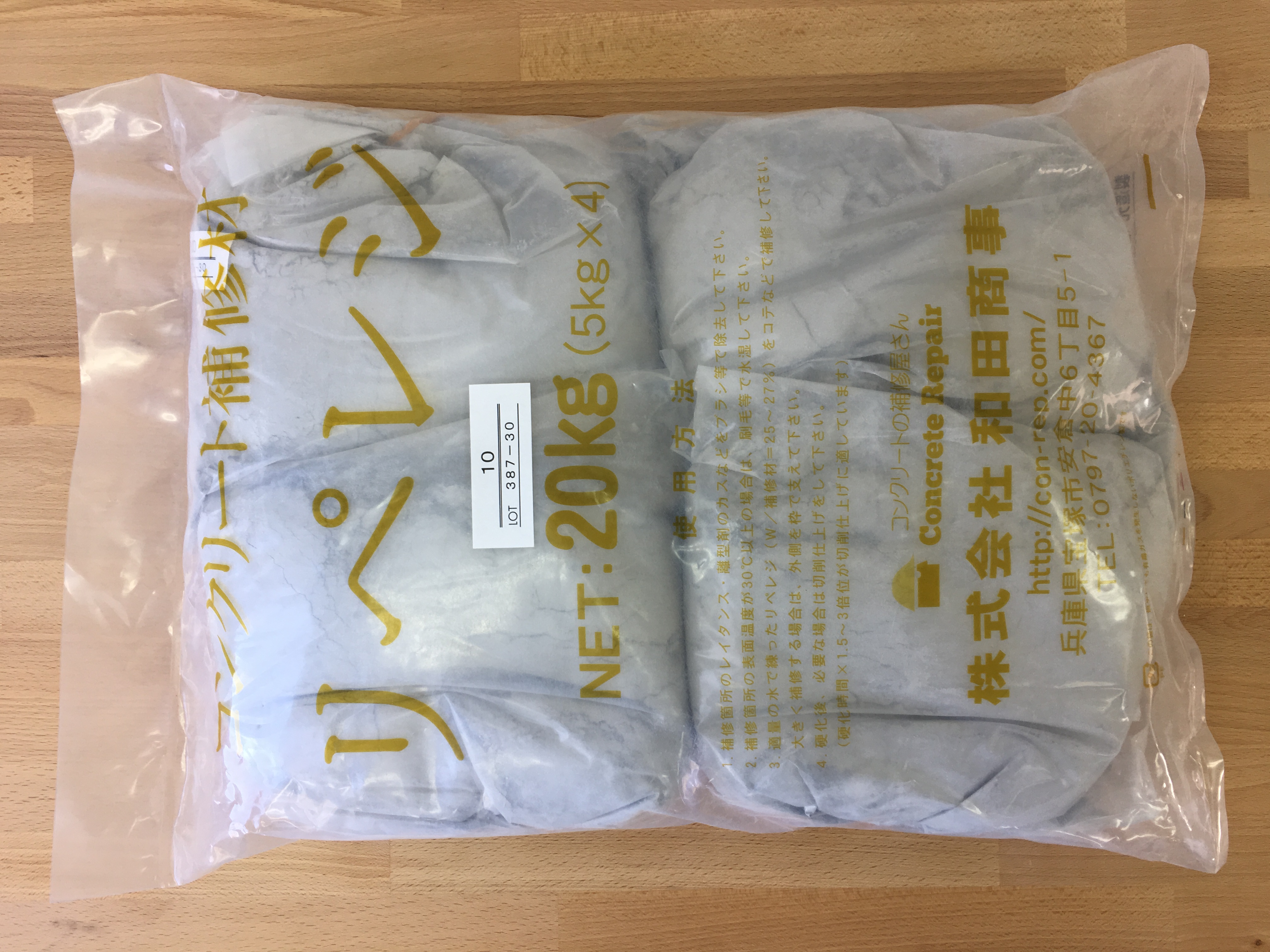

What you can buy at our shop

-

C Repair Color (each color separately)

C Repair Color (each color separately)

-

C Repair Color (7colors set)

C Repair Color (7colors set)

-

Tone Color (Black, Yellow, Red)

Tone Color (Black, Yellow, Red)

-

Repair Resin (each color, each number)

Repair Resin (each color, each number)

-

C Repair Lining

C Repair Lining

-

Rubber Bowl

Rubber Bowl

-

Cationic substrate adjustment primer "Royal W21"

Cationic substrate adjustment primer "Royal W21" -

Pattern Pad (Large / Small)

Pattern Pad (Large / Small)

-

Wagner Flexio 570 Electric Spray Gun

Wagner Flexio 570 Electric Spray Gun

-

Level Grinding Wheel # 36 # 80

Level Grinding Wheel # 36 # 80